Have you ever walked into a room and noticed a slight bump or gap in the vinyl flooring? It’s an eyesore, isn’t it? This is where cold weld bonding glue comes in, a secret weapon for achieving that perfectly seamless look in your vinyl flooring. Just like a skilled seamstress stitches together fabric, cold weld glue seamlessly joins vinyl planks or tiles, creating a unified and beautiful surface.

Image: www.yajuds.com

This article will delve into the world of cold weld bonding glue for vinyl flooring. We’ll explore what it is, how it works, and the benefits it offers. You’ll also discover expert tips for using cold weld glue effectively, ensuring your vinyl flooring is as smooth and flawless as it can be.

Understanding Cold Weld Bonding Glue

Cold weld bonding glue, also known as vinyl seam sealer, is a specialized adhesive designed for joining vinyl flooring planks or tiles. Unlike traditional adhesives, cold weld glue creates a bond that’s virtually invisible, leaving no noticeable seams. This creates a seamless flow to your flooring, making it appear like one solid piece.

The glue typically comes in a tube or bottle with a nozzle that allows for precise application. It works by chemically fusing with vinyl to create a strong, durable bond that resists moisture, wear, and tear. The cold weld process eliminates the need for heat or pressure, making it a convenient and efficient solution for both professionals and DIY enthusiasts.

How Cold Weld Bonding Glue Works

Cold weld bonding glue works on a chemical level to achieve its seamless bonding. When the glue is applied, its solvent evaporates, leaving behind a strong polymer that creates a strong, seamless bond with the vinyl. This polymer acts as a filler, bridging the gap between the vinyl planks and essentially making them one continuous surface.

The process involves applying a thin, even line of cold weld glue along the seam where the vinyl planks or tiles meet. The glue is then allowed to dry, typically within a short timeframe, before heavy foot traffic is allowed on the newly bonded area.

Benefits of Using Cold Weld Bonding Glue

Cold weld glue offers numerous benefits for vinyl flooring installation:

- Seamless Finish: It creates a continuous, uninterrupted surface, enhancing the overall aesthetic of your floor.

- Durable Bond: Cold weld bonding glue is designed to withstand wear, tear, and moisture, making it ideal for high-traffic areas.

- Easy Application: It’s relatively easy to use and doesn’t require any specialized tools.

- Fast Drying Time: The glue dries quickly, minimizing the time it takes to install the flooring.

- Cost-Effective: Cold weld bonding glue is an affordable solution compared to other bonding methods.

Choosing the right cold weld glue is crucial for achieving those impressive results. Carefully select a high-quality product that’s specifically designed for vinyl flooring.

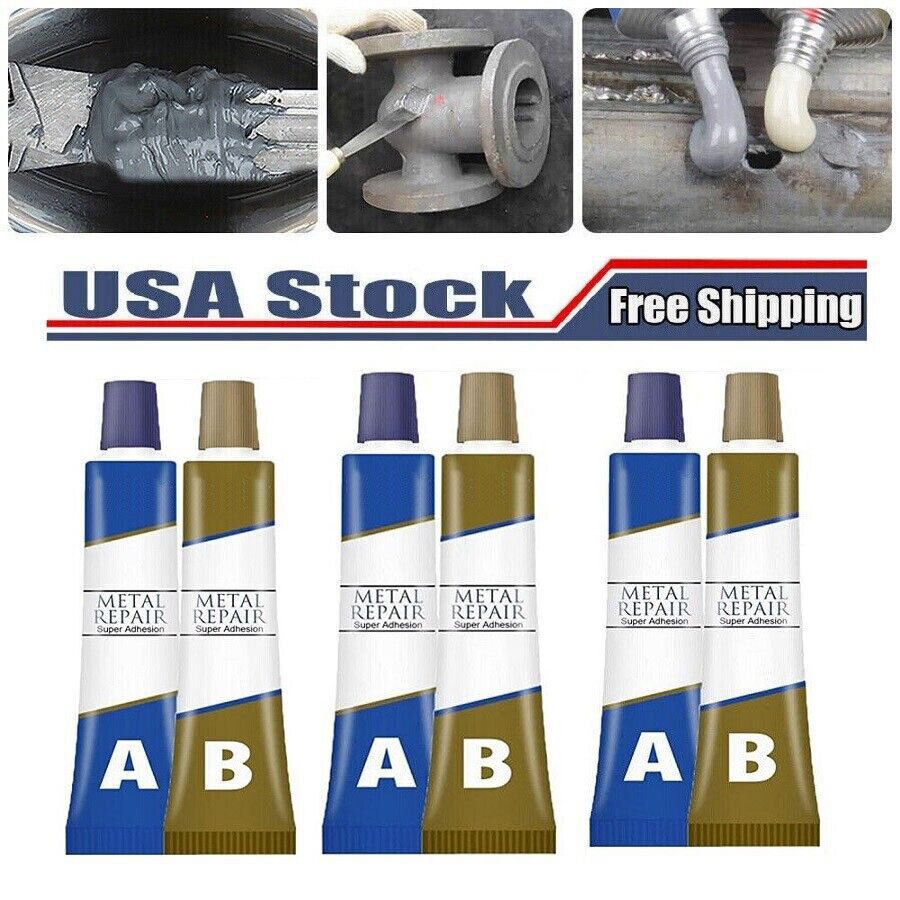

Image: www.ebay.com

Tips for Using Cold Weld Bonding Glue

Follow these tips to ensure your cold weld bonding experience is smooth and to achieve a perfect finish:

- Prepare the Surface: Clean the vinyl floor thoroughly to ensure the glue adheres properly.

- Apply Evenly: Use a steady hand when applying the glue to create a thin, consistent line along the seams.

- Use a Tool to Spread: To ensure smooth, even coverage, use a tool like a putty knife or spread the glue with a spatula.

- Clean Excess Glue: Immediately remove any excess glue from the surface to prevent unsightly marks. Consider using a damp cloth to wipe away excess glue.

- Allow Adequate Drying Time: Follow the manufacturer’s instructions regarding drying time.

- Test First: On a less visible area of your vinyl flooring, perform a test application to ensure compatibility before applying the glue on a bigger scale.

FAQs

Q: What types of vinyl flooring does cold weld glue work with?

A: Cold weld bonding glue is compatible with most types of vinyl flooring, but it’s best to confirm with the manufacturer for the most accurate information.

Q: How long does it take for cold weld glue to dry?

A: Drying time varies based on factors like temperature and humidity. Refer to the product instructions (typically on the packaging) for the recommended drying time.

Q: Is cold weld bonding glue waterproof?

A: It’s designed to be moisture-resistant, but it’s important to follow the manufacturer’s instructions carefully. Additionally, avoid excessive water or moisture.

Q: Is cold weld glue safe to use indoors?

A: Yes, the glue is typically safe to use indoors, but it’s always a good idea to have adequate ventilation. Read the product label for any specific safety precautions.

Q: Can I use cold weld glue to fix a gap in my existing flooring?

A: Yes, cold weld glue can be used to fill small gaps, but it might not be the ideal solution for larger gaps or significant damage. For repair cases, consult a professional for advice.

Cold Weld Bonding Glue For Vinyl Flooring

Conclusion

Cold weld bonding glue is a valuable tool for anyone seeking a seamless finish for their vinyl flooring. By following the tips provided and selecting the right product, you can achieve a professional-looking result that enhances the beauty and durability of your floors. Remember to research and ensure you select the best glue for your specific needs.

Are you interested in learning more about cold weld bonding glue, or have you used it for your flooring projects? Let us know your thoughts!